Packaging foam custom cutting service

Die Cut Foam Packaging Service

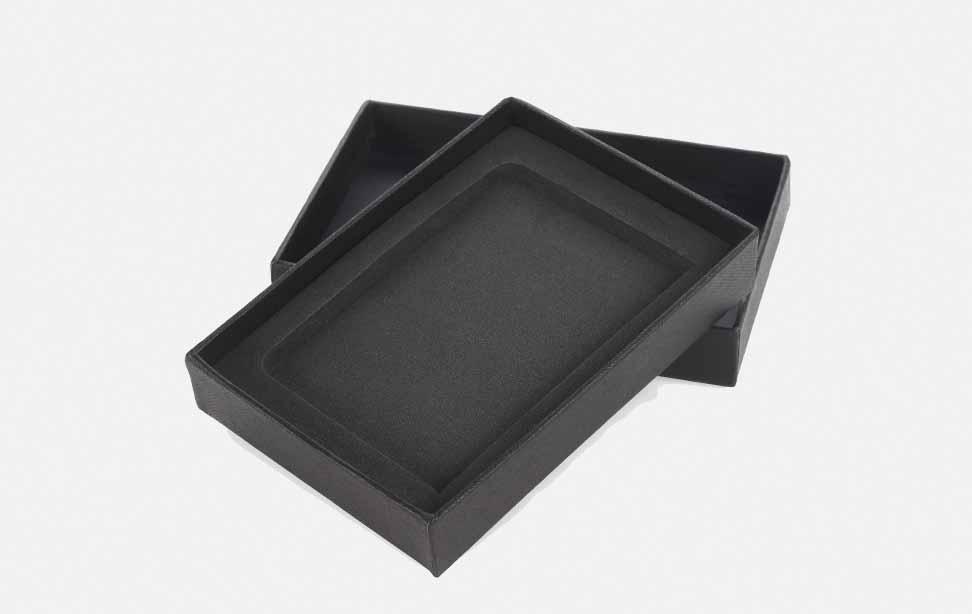

Packaging foam doesn’t just protect the products it encases. It is easy to forget that packaging foam can also be a very important part of product presentation. What we also tend to forget is that foam can be cut to provide custom foam packaging for any shape or size of item. This applies to you whether you are a mass manufacturing company, or an individual creating hand-thrown pottery.

“Inside the box thinking” for die-cut foam packaging solutions

While every business is encouraged to ‘think outside of the box’ when it comes to marketing, here at Entwistle Group we went in the opposite direction and did our thinking ‘inside the box’, which is why we have invested in state-of-the art machinery that can produce custom foam packaging in the form of die-cut foam, die-cut foam inserts and die-cut foam packaging.

Our foam of preference is:

- LD33 foam

- 3mm, 5mm & 15mm thickness

Product packaging can create the wrong first impression

How many of you have received a package through the post, perhaps an online purchase, which has arrived in an ordinary-looking box or presentation sleeve and when you open it up, the product you have purchased is wrapped in some paper or held within a cardboard mounting to protect it. Sure, the packaging has done its job, but it also conveys a subliminal message about the product. It is average, of little importance, and you shouldn’t expect too much from it.

You should note that rather than describe a specific product, we have left that deliberately vague, for one specific reason. Die-cut foam packaging can be used for anything and everything that needs to be protected against accidental damage when being transported. This can include pottery, glassware, technical products and everything in between.

Entwistle Group packaging solutions can ensure you create the perfect first impression for your products, and more besides

Our move into the area of die cut foam packaging was logical, thanks to recent advances in finishing equipment technology. At the Entwistle Group we have had tremendous success with our printed boxes on our two Arizona flat bed printers, which not only help to promote a corporate or branding image, but they help to create the ‘wow!’ factor.

Our flat bed print machines can not only provide rich imagery for the outside of your boxes, but the card the imagery is printed on can be cut and creased so that a sturdy box can be created from the card alone, without the need for glue or tape, and also without needing a degree in Origami!

However, that is only one part of packaging requirements, as the inside of the box can be just as important as the outside when it comes to the ‘customer experience’. Considerable market research has been carried out on the importance of packaging, which has led to the following key insights:

- Often, the packaging for your product is the first touchpoint that customers have with your brand beyond your website or sales portal

- Quality packaging enriches the ‘customer experience’ and encourages repeat business

- Premium packaging informs your customer that you care about the product(s) they have bought

- Good packaging eliminates the potential for ‘disappointment’ when the purchased product is delivered

- How many product reviews have you read online that begin with the words “Arrived in a great-looking box and was extremely well packaged” or words to that effect? There are examples of this everywhere you look.

- A positive unpackaging experience leads to a greater chance of product recommendation between friends and acquaintances

Colour-coordinated foam packaging

Of course using the wrong colour of foam can undo all the worthwhile effort you have put into the design and production of your product packaging. At the Entwistle group we can provide die-cut foam inserts for packaging boxes not just in any shape or format, but also in a range of colours.

No minimum order size for die-cut foam

There used to be a time when small businesses were at a disadvantage when it came to printed materials and packaging products. It only made financial sense once a minimum order size had been reached, often well into the hundreds, if not thousands of units.

At the Entwistle group we are please to say those days are long gone and today we are delighted to have many clients who come to us for even single-digit order numbers. Thanks to digital technology and the ease at which our printing, folding and foam die-cutting equipment can be set up for each individual task, unit costs for even the smallest of runs are now extremely cost effective.